The successful construction of a masonry project depends heavily on the expertise of carpenters in creating and managing formwork for concrete pours. Their role involves selecting high-quality, moisture-resistant timber to construct precise wooden molds that shape and support wet concrete, determining the final structure's dimensions and finish. Carpenters must assemble these molds with precision, ensuring alignment and secure fastening to prevent distortion or leaks. Integrating reinforcement bars within the formwork is essential for a strong bond between the concrete and steel, enhancing structural integrity. Attention to detail by carpenters during this stage is crucial for achieving high-quality finishes without costly corrections. Efficient formwork management by skilled carpenters leads to faster project completion, cost savings, and reduced risks of failure or misalignment. Carpenters' ability to interpret architectural plans and translate these into practical formwork that aligns with design intent is critical. Their knowledge of various materials, adaptability, and attention to detail are indispensable for meeting diverse project demands and maintaining timelines. The quality of the initial formwork work significantly influences a structure's longevity and integrity. In the broader scope, carpenters establish a robust foundation for masonry projects, enabling other trades to build upon their precise work, ensuring both the immediate success of the concrete pour and the long-term robustness of the construction.

Constructs formwork serves as the backbone of masonry projects, enabling architects and builders to shape concrete into the structures that define our urban landscapes. This article delves into the nuances of formwork construction, offering a comprehensive guide for carpenters who play a pivotal role in this specialized craft. From material selection to safety protocols, we explore the essential elements that ensure efficient concrete pours and structural integrity. Carpenters’ expertise is paramount; their skillful hands shape not just wood and steel, but also the very foundations of our built environment. We will examine technological advancements, address common challenges, and provide insights into training for formwork specialists. Additionally, we’ll highlight cost-effective strategies for maintaining formwork equipment, ensuring that each project is completed with precision and safety. Join us as we navigate the intricate world of constructs formwork, where every measurement and design choice contributes to the enduring structures that rise from the ground.

- Understanding Constructs Formwork: A Mason's Guide to Efficient Concrete Pours

- The Role of a Skilled Carpenter in Constructs Formwork Projects

- Material Considerations for Formwork Construction by Carpenters

- Designing the Formwork Frame: Key Factors for Structural Integrity

Understanding Constructs Formwork: A Mason's Guide to Efficient Concrete Pours

When constructing a masonry project, the formwork, also known as shuttering, plays a pivotal role in shaping the structural integrity and precision of the final concrete structure. A mason’s guide to efficient concrete pours begins with a thorough understanding of formwork, which is where carpenters come into the picture. Skilled carpenters are responsible for crafting wooden molds that are both durable and accurate to the design specifications. These molds not only provide the necessary support for wet concrete but also determine the dimensions, angles, and finish of the hardened structure.

The effectiveness of a concrete pour is significantly influenced by the quality and preparation of the formwork. Carpenters must select appropriate timber, ensure its straightness and strength, and treat it to resist moisture and prevent decay. The assembly of the formwork requires meticulous alignment and secure fastening to maintain the intended shape and size without distortion or leaks. Additionally, carpenters must incorporate necessary reinforcement bars within the formwork to enhance the bond between the concrete and the steel, ensuring a stronger final product. Attention to detail in this phase of masonry is crucial for a successful pour, as it directly affects the quality of the finished construction. Mastery of formwork techniques by carpenters not only streamlines the pouring process but also contributes to cost savings and project timelines by minimizing corrective work and rework due to structural failures or misalignments.

The Role of a Skilled Carpenter in Constructs Formwork Projects

In constructs formwork for concrete pours in masonry projects, the role of a skilled carpenter is pivotal. These professionals are responsible for assembling, positioning, and dismantling the wooden or metal molds that give shape to the concrete structures. The precision and craftsmanship of a carpenter ensure the formwork’s integrity, which in turn affects the quality and durability of the final construction. A carpenter must meticulously measure and cut materials to precise specifications, often working with complex designs and tight tolerances. Their expertise in joining materials without compromising structural stability is crucial for the safety and efficiency of the project. The carpenter’s attention to detail and ability to adapt to different project requirements make them indispensable in the construction process. They must also be adept at interpreting architectural plans and specifications, translating these into tangible formwork that aligns with the intended design and function.

The impact of a carpenter’s work extends beyond the immediate tasks associated with constructs formwork projects. Their contributions to project timelines are significant; by executing their duties correctly, they enable the subsequent concrete pour to proceed as planned, avoiding costly delays or rework. Moreover, the longevity and integrity of a structure often hinge on the quality of the initial formwork. A carpenter’s skill set not only includes the physical construction of the formwork but also understanding the properties of materials used, such as wood, steel, and plywood, to ensure they are suitable for the intended application. In this way, the skilled carpenter is a linchpin in the successful completion of masonry projects, providing a solid foundation upon which other trades can build.

Material Considerations for Formwork Construction by Carpenters

When constructing formwork for concrete pours in masonry projects, the role of carpenters is pivotal due to the precision and material selection required. Carpenters must carefully consider the types of wood or engineered materials that will be used to create the formwork, as these materials dictate the strength, durability, and longevity of the masonry structure. The choice between softwoods like pine or fir, which are more cost-effective but may require more frequent replacement, and hardwoods such as oak or maple, which offer greater resilience against wear and moisture, is a key decision for carpenters. Additionally, engineered materials including plywood and composites have gained popularity due to their consistency in performance and dimensional stability. The thickness of the boards, the type of fasteners used, and the overall design must be tailored to the specific requirements of the project. Carpenters should also consider the environmental impact of their choices, opting for sustainable materials that comply with green building standards, thereby ensuring the formwork not only supports the concrete effectively but is also environmentally responsible. Proper maintenance and regular inspection protocols are essential to ensure the formwork remains in optimal condition for multiple uses, extending its lifespan and contributing to cost savings over time. The skillful application of these material considerations by carpenters is what lays the foundation for a successful concrete pour and a robust masonry project.

Designing the Formwork Frame: Key Factors for Structural Integrity

In the realm of masonry projects, the designing of a formwork frame is pivotal for ensuring the structural integrity of concrete pours. A meticulously designed formwork not only facilitates the pouring and curing of concrete but also significantly impacts the durability and safety of the final structure. The formwork must be engineered to withstand the weight and pressure exerted by fresh concrete, which necessitates a robust design that accounts for the loads during construction. A seasoned carpenter brings expertise in selecting appropriate materials, understanding load bearing capacities, and applying mathematical precision to create a frame that aligns with the architect’s blueprint. Key factors such as the type of timber used, the connection points between components, and the overall stability of the frame are critical considerations. The carpenter must calculate the stress points and ensure that the formwork is both rigid enough to maintain its shape and flexible enough to allow for the concrete to be smoothly poured and removed without causing damage or distortion. Additionally, the design must incorporate proper drainage to prevent water accumulation within the form, which could compromise the structural integrity of the hardened concrete. By adhering to these principles, a carpenter can construct a formwork frame that not only serves its immediate purpose but also contributes to the long-term performance and reliability of the masonry project.

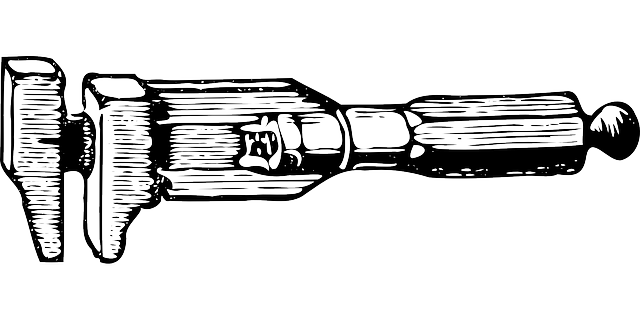

The alignment and precision of each component within the formwork are paramount to prevent misalignment or uneven concrete pours, which could lead to structural weaknesses. A carpenter skilled in this craft understands that the accuracy of the formwork’s dimensions directly affects the final structure’s quality. The use of advanced tools and measurement instruments allows for precise calculations and adjustments during the construction process. Furthermore, the carpenter must consider environmental factors such as temperature and humidity, which can affect both the wood used in the formwork and the curing process of the concrete. Proper ventilation within the formwork is essential to maintain optimal conditions for the concrete to cure effectively. Incorporating these considerations into the design of the formwork frame ensures that the structure will be sound, safe, and capable of withstanding the intended loads once the concrete has hardened. The expertise of a carpenter in navigating these complex factors is indispensable for the successful completion of masonry projects involving concrete pours.

In conclusion, the intricate process of constructing formwork for concrete pours in masonry projects is a testament to the skilled craftsmanship of carpenters. By carefully considering the materials and design elements necessary for structural integrity, these professionals ensure that each pour lays a solid foundation for the structure’s future strength and longevity. The insights provided in this article aim to guide masons through the nuances of formwork construction, emphasizing the critical role that carpenters play in the building process. A comprehensive understanding of formwork, as detailed here, is indispensable for achieving precision and efficiency in concrete pours, ultimately contributing to the overall quality and durability of constructed projects.